Print Failures

Prints Not Sticking to the Build Plate

-

Unlevel Build Plate: Relevel the build plate, and ensure you have equal tension at each corner. Refer to How to Level Build Plate.

-

Insufficient Bottom Layer Exposure Time: Increase your bottom layer exposure by 3-5 seconds. If the bottom layer exposure time is significantly higher than the manufacturer recommened time, the issue is likely something else.

-

Too Fast Lift Speed: For bottom layers, use a slow lift speed. We recommend between 40mm/min and 60mm/min.

-

Dirty Build Plate: Was the build plate properly cleaned? Refer to How to Clean Build Plate.

-

Cold Build Plate: Pre-heat the build plate using a mini heater or store in a climate controlled environment. Example portable space heater.

-

Improper Bottom Layer Count / Raft Thickness: Refer to Bottom Layers & Raft Height.

-

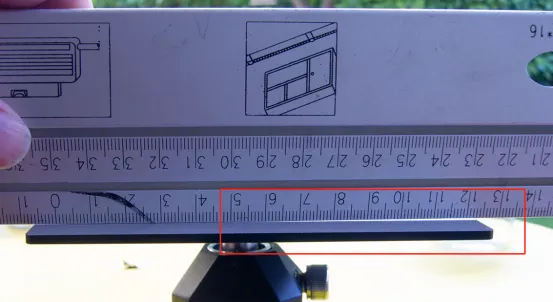

Deformed Build Plate: Unfortunately, some build plates come from the factory with defects that make them not perfectly flat. In these situations, reach out to the printer manufacturer support contact.

Prints Detaching from Supports

-

Insufficient Normal Layer Exposure: Verify the exposure time using a calibration test, and increase the normal layer exposure time if necessary.

-

Too Small Support Tips: Increase the support tip sizes. Using too small support tips is a common issue we see, even with pre-supported models.

-

Too Few Supports: Add more supports. If you have verified that you are using a good exposure time with adequate support tip sizes, you may simply need to add more supports. Refer to our Quick Support Guide for more information.

-

Too Fast Lift Speed: For normal layers, we recommend using an initial lift speed between 60mm/min and 90mm/min. If you want to experiment using faster lift speeds, only do so after you are getting successful prints.

-

Large Cross Section Areas: Large cross section areas significantly increase the pull force between the FEP and your print. Orient the model to help reduce the amount of large cross section areas.

-

Cold Resin: Cold temperature slows down the chemical reaction of photopolymerization. Most resins typically perform well between 70F-83F (21-28C).

-

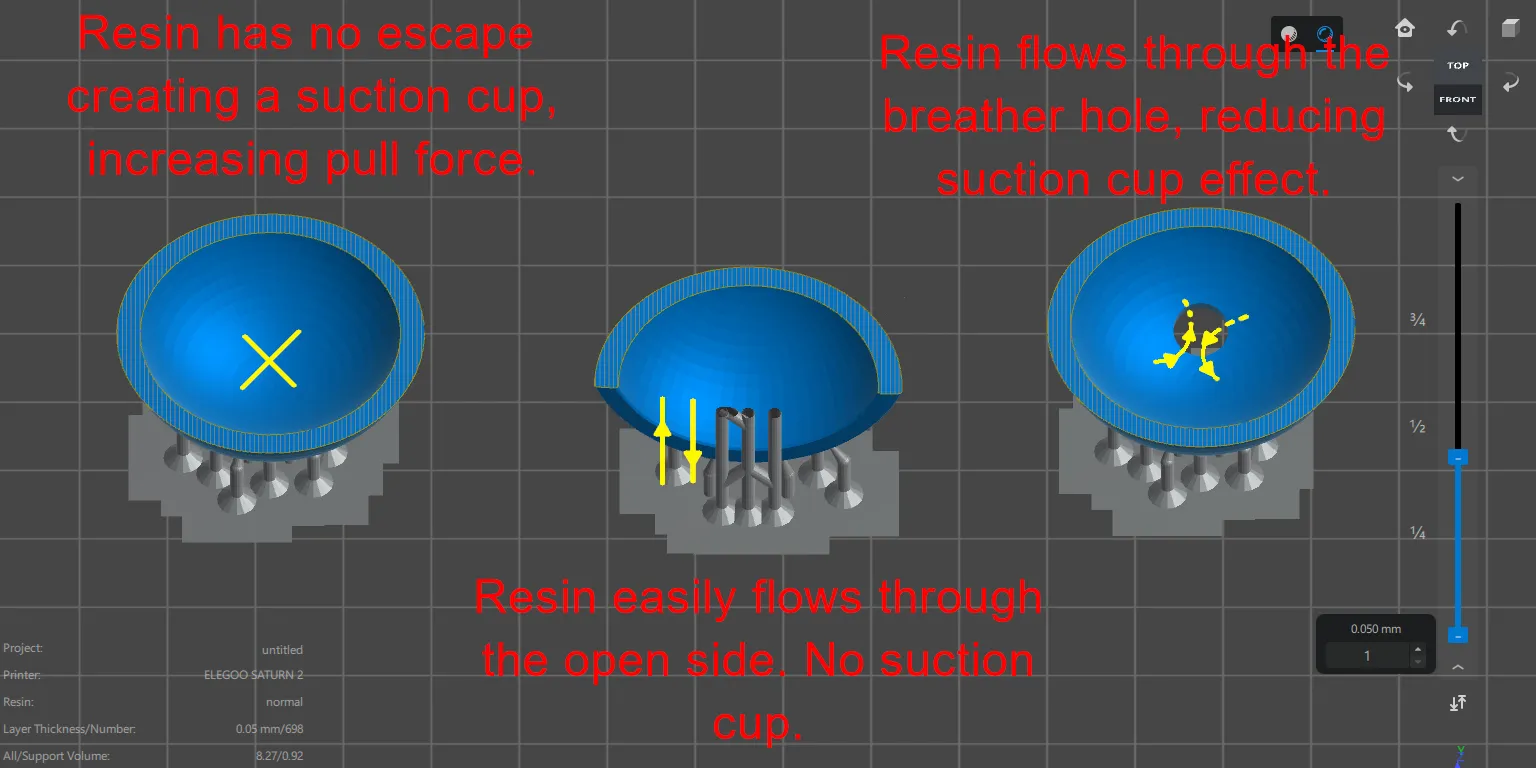

Suction Cup Effect: Most common with hollow prints, suction cup-like shapes without any breather holes drastically increase the pull force between the print and FEP.

-

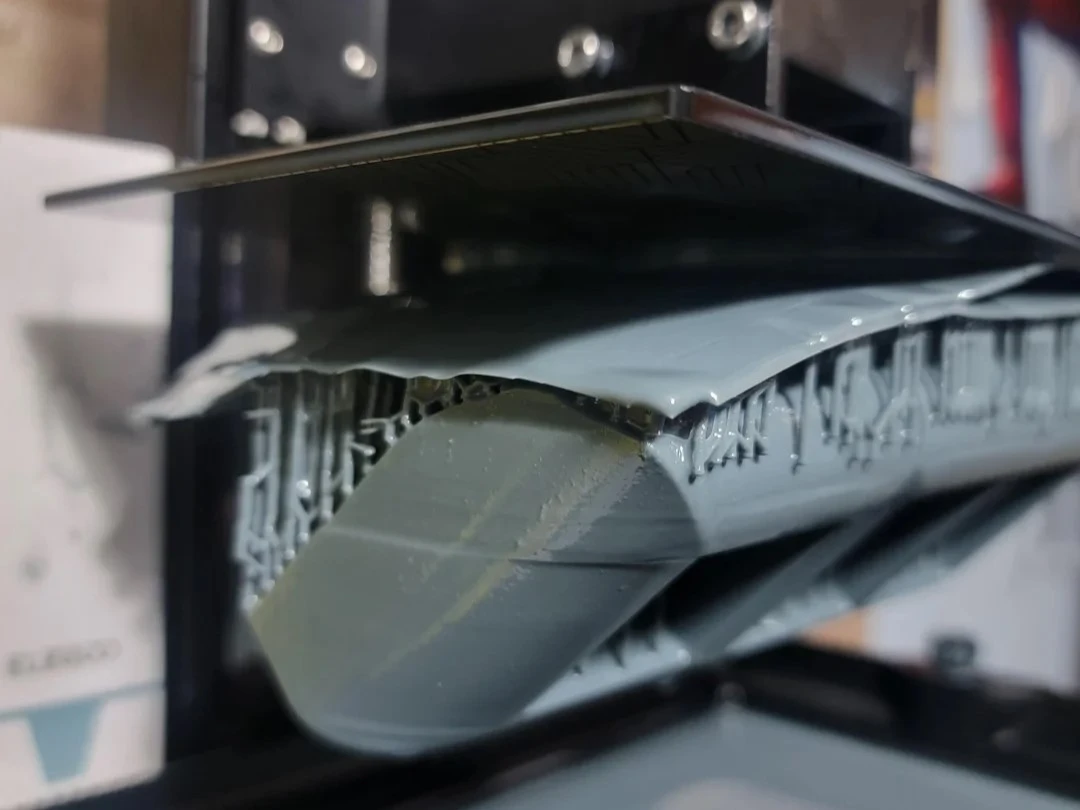

Damaged FEP: Over time, FEPs become scratched, cloudy and worn. Inspect the condition of your FEP.